Page 1 of 1

Re-winding Alternator

Posted: Wed Aug 13, 2014 7:14 pm

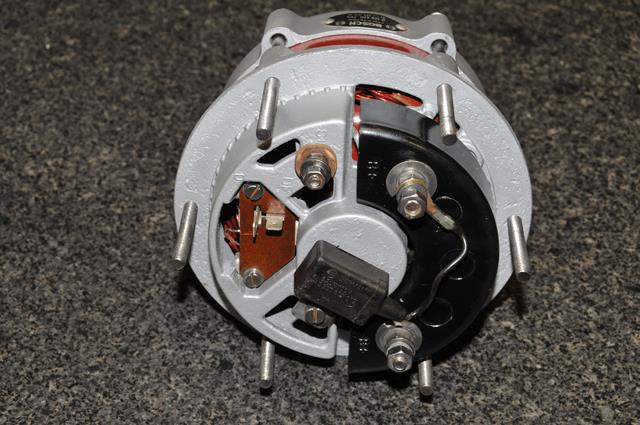

by bikmakr

Concerning the subject of re-wiring the stator to increase alternator output. I found a local shop (to me), that rewound the stator with larger diameter wires and rebuilt the rest, even using Bosch paint. Output tests at 70amps at 2200 shaft rpm. I have no affiliation, just wanted to pass along the info. Dean is willing to accept yours, rebuild and ship it back. Total was less than $300. Much less than a new one. The caveat is less output at idle, but not really a concern to me. See pictures.

- DSC_4920-reduced.jpg (94.48 KiB) Viewed 3056 times

- DSC_4919-reduced.jpg (92.54 KiB) Viewed 3056 times

Dean's Auto Electrical & Parts

Dean Okano, Owner

205 North I Street, Suite A

Livermore, CA 94551

Phone: 925-443-3323

Fax: 925-443-9195

Re: Re-winding Alternator

Posted: Wed Aug 13, 2014 7:30 pm

by krick3tt

When you say less output...is that less than the 70 A that you quote or less than the original would put out?

Re: Re-winding Alternator

Posted: Wed Aug 13, 2014 8:29 pm

by Jimm391730

Glad you are happy with the rebuild. I hope they upgraded the rectifiers (diodes) for twice the current, too.

Output tests at 70amps at 2200 shaft rpm

Since the alternator pulley to crankshaft ratio is roughly 2:1, 2200 rpm at the alternator shaft is about 1100 rpm at the engine. Pretty good if its producing 70A at that engine speed.

But the question remains: will you upgrade the wiring gauge from the alternator, through the Molex connector (it won't take 70A for long), and continue on from the other side of the Molex to the starter? All of this really must be upgraded to take advantage of what the alternator can create.

And frankly, I've never seen anybody that had loads (excepting winches, which are used in short duration) that exceeded the capacity of the stock alternator. I have almost 600W of extra lighting, and all of those (which never are needed at the same time), ignition/fuel injection, headlights, fan, brakelights, refrigerator, etc. running at once have not overtaxed the stock alternator (it is still capable of keeping the electrical system at ~27 volts with all of that running, even at idle). Regardless, it is good to know that you found a shop that looks like can do a quality job of rebuilding and/or improving the stock alternator.

Re: Re-winding Alternator

Posted: Wed Aug 13, 2014 11:40 pm

by bikmakr

At Idle, it will produce less current than stock. It's a tradeoff. If you are crawling for extended periods, maybe it's not for you. My air conditioning (32K BTU) draws 20amps, so I felt it would be a good upgrade over the 35 amp stock windings. I ran 6 gauge welding cable past the molex, directly to the starter terminal. I have upgraded to LED head and tail-lights so that helped my overall current budget.

Re: Re-winding Alternator

Posted: Thu Aug 14, 2014 12:26 am

by Jimm391730

I ran 6 gauge welding cable past the molex, directly to the starter terminal.

Good choice, that should do it! Welding cable can be soft (so it is flexible), if you haven't done so you might put some split or spiral loom around where it might chafe.