So off to Lowe's I went.

Additional photos are here:

http://picasaweb.google.com/pinzgauer.d ... rPinzgauer

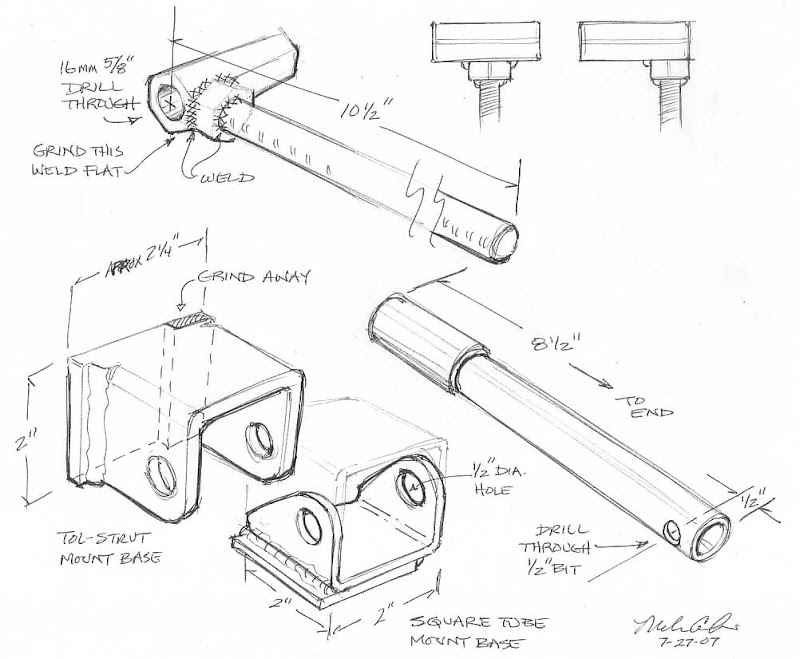

This is the custom tool that I made instead of buying the tool for $345.00 Most of the parts can be found at Lowe's or any other large hardware store.

When you are shopping make sure the 5/8-11 threaded rod slides easily into the 1/2" heavy wall conduit, there is a welded seam running down the inside and varies in size from pipe to pipe. So test fit it before you buy or you will have to ream it out with the 16mm or 5/8" drill.

Main parts: (2) 5/8-11 x 12" rod....(2) 1/2" x 10" heavy wall conduit pipe threaded both ends...(2) 1/2" conduit joining nipples....(4) 5/8-11 rod joining nuts....(2) 5/8-11 nuts....(6) 5/8 fender washers....(20) 1/2" fender washers....(2) 1/2" x 3" bolts....(2) 1/2" Nylock nuts.

These I had to get from McMaster Carr....(2) 16x1,5x100mm bolts Part#91180A830....(2) U-Brackets for pivot base Part#33145T53.

Tools needed: 16mm or 5/8" drill bit....1/2" drill bit.... Hand drill....Table vise....Metal band saw or air cutoff tool....Angle grinder....Mig welder or someone that will weld it for you, welding only takes 10-15min. The tool can be made in a day.

Only welding is at the head mount with small nut welded to the long nut " one in center and one at end", then threaded rod welded into nut. Now you have to drill out the long nut with a 16mm or 5/8" drill. Thread on the Long Nut before cutting the rod. Now cut the threaded rod off so it is 10 1/2" long from center of mounting hole to end of threaded rod.

On to the base. Make sure the threaded rod still runs through conduit pipe smoothly. Thread on the connecting nipple to one side of the 10" conduit pipe. Measure from top of connecting nipple 8 1/2" and cut off excess of conduit pipe. At the cut off end drill a 1/2" hole through the pipe centered 1/2" up from end.

Now take the Strut channel support base and cut it down 1/4" above the lowest hole in the U-channel part, radius all edges. Cut all of the base away leaving it 2" high" open end of U-channel will be pointing down" Now the two parts have to be made diffrent but in a mirror image to each other. With the U-channel facing down set them side by side. The inside edges " facing each other must be cut off flush with the U-channel, most of the weld will have to be cut off but that is fine the weld will still hold. The outside edges get cut off with a 1/4" lip to maintain the full weld. Radius all sharp edges. Assemble the conduit pipe to the base with the 1/2" bolt and washers.

On the back side of the Most offset side cut a recess to accomodate the stop ring flange, you'll see when you test fit the parts to the axle.

The 16x1,5x100mm bolt is long enough to use the washers as in the photos, if you don't want to use the washers a 90-95mm bolt will work.

The pivoting base was used to make the base more stable and to minimize the accute pressure exerted by the sharp angle of the original V style rocking tool base.

Good luck and enjoy.

Miles